Cyclotron-Produced Radiotracers

The synthesis of most PET radiotracers requires a machine called a cyclotron. This is a circular particle accelerator that is used to bombard chemical targets with charged particles to form new isotopes.

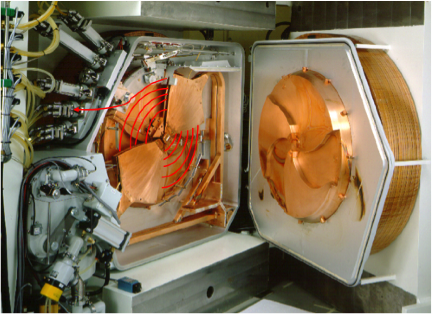

The cyclotron opened to show the path taken by the accelerated charged particles. Different targets are stored in the chambers at the upper left. Photo credit: John Clark

By using different target materials, four of the most commonly produced radioisotopes for PET imaging are shown in the table below:

| Radioisotope | Target | Half-life |

|---|---|---|

| 18F | 18O | 110 minutes |

| 11C | 14N | 20 minutes |

| 13N | 16O | 10 minutes |

| 15O | 15N | 2 minutes |

The newly formed radioisotope is automatically transferred to a hot cell. Hot cells are shielded chambers where a series of automated chemical reactions incorporate the radioisotope into a useful chemical compound. Shielding is required throughout the process due to the high amounts of radioactivity involved.

Hot cells used for radiotracer production

Automated synthesis unit for producing FDG

After the radiopharmaceutical has been synthesized in the hot cell, it undergoes quality checks to ensure it is safe for injection into a patient.

18F-based radiopharmaceuticals have a long enough half-life that a large quantity can be synthesized in the morning for use throughout the day. Shorter-lived isotopes (such as 15O) have to be synthesized just before they are delivered for injection.

The radiopharmaceuticals formed in this process will all have different biological pathways in the body (known as pharmacokinetics), each giving different physiological information about the patient.